Dual Tube vs Monotube Shock Absorbers

5th Oct 2023

In this Cruisemasterclass we explore the different types of shock absorber systems, the role they play in suspension systems and some tips for maintaining them to ensure ideal ride characteristics.

Cruisemasterclass Episode 18: Shock Absorbers | Dual Tube vs Monotube

How Shock Absorbers Work

Shock absorbers, also known as dampers, are a component of a suspension system with the primary job to optimize the contact between the tyre and the ground. This provides optimized handling and ride characteristics, which is achieved by controlling the energy that is stored in the spring when travelling over various terrains.

The shock absorber works by converting the kinetic energy produced from the spring into thermal energy that is dissipated through heat transfer into the environment.

What Are Shock Absorbers?

Shock absorbers have two ends, both with eyes or pins used to mount them to the suspension system. One end is attached the chassis and the other to the control arm or axle housing on live axle suspensions.

Under the outer guard of the shock is a piston rod connected to one eye, with the other end housing a piston. The body of the shock is filled with oil allowing the piston to slide within the tube creating a restriction of flow. The piston has a series of holes used to control the flow at low speed along with shims or valves to control mid to high speeds.

By controlling the viscosity of the oil, design of the valve system and the size of holes gives us the ability to create specific damping characteristics. These are designed to specific vehicle particulars like spring rate, weight and geometry, allowing us to provide the best performance possible for each scenario.

Types of Shock Absorbers

There are two main types of shock absorbers on the market that are commonly used in trailer suspension systems, these are the dual tube and monotube constructions. In the sections below we will outline how each system works and some of the benefits and disadvantages of each system.

Dual Tube Shock Absorbers

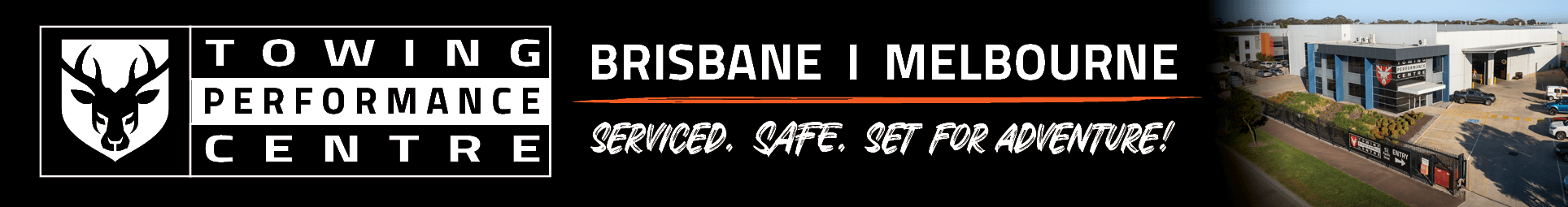

As the name suggests, dual tube shock absorbers house two tubes within the body. The central tube is called the working tube, with the other tube being the reserve. These are concentric, with the working tube containing the piston and piston rod. The diagram below is a good visual to demonstrate the innerworkings and positioning of components.

As the shock absorber compresses, the piston and rod displace an amount of oil which transfers to the reserve through the gap between the two tubes.

This action produces the damping effect via both the piston and the two tubes. In most dual shock absorbers there will also be either a low pressure gas or foam sleeve in the reserve tube to reduce cavitation, which is little air bubbles that get formed when the shock absorber works hard.

Benefits of Dual Tube Shock Absorbers

One of the benefits of dual tube shock absorbers is it's compact design allowing it to fit into most suspension geometries and its naturally protective design. We find that dual tube shock absorbers, when correctly designed and valved are suitable for the majority of off-road conditions you'll encounter in Australia.

Dual Tube Shock Absorber Disadvantages

Some common disadvantages of dual tube shock absorbers that you may encounter are lag and fade.

On particularly rough terrains or corrugations where the shock absorber is working hard, the cavitation that forms reduces the viscosity of the oil which equivalates to a reduction of damping performance. This is referred to as fade, which is not ideal as it reduces the contact between the tyre and the ground affecting handling.

With both a piston and a foot valve providing damping in dual tube shocks, when they start to work hard you get another phenomenon called lag. This happens when the oil being sucked out of the working tube and the bottom valve can't keep up, this results in a flat spot leading to damping degradation.

Mono Tube Shock Absorbers

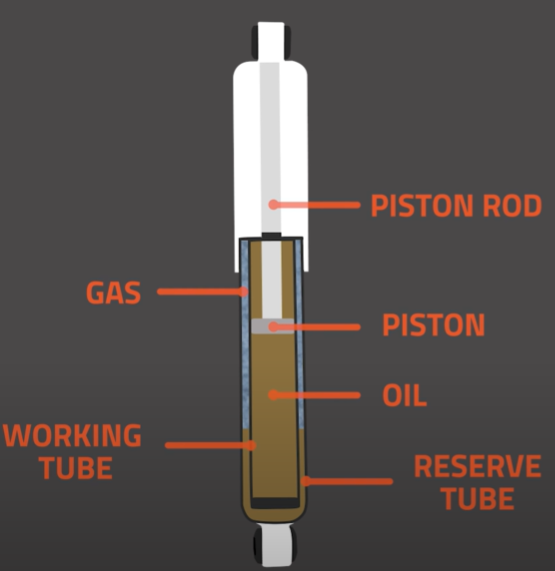

Mono tubes make use of a singular working tube that doesn't have a reserve tube like that of the dual tube shock absorber, utilizing a piggyback reservoir design instead. This design allows for much bigger pistons which provides better damping control to obtain higher damping forces. Below is an illustration of a monotube shock.

As you can see the piggyback reservoir stores the volume of oil that is displaced by the piston and houses a small additional piston which moves up and down with the movement of the rod. Other monotube designs utilize a remote reservoir that is attached to the end of a hose to transfer the displaced volume.

Monotubes shocks are typically high pressure in the range of 150psi, this pressure on the little piston generates a substantially higher load on the oil. This reduces cavitation to the point where its relatively non-existent in most cases, allowing you to travel over rougher terrain whilst maintaining damping performance without having the characteristics of fade.

Benefits of Monotube Shock Absorbers

Because the damping is only occurring on the piston, it isn't susceptible to the lag effect like that of the dual tube systems, in turn producing better contact with the ground. Monotube shocks also reject the heat they collect a lot more efficiently as there is no space between the working tube and the atmosphere like that of the dual tube varieties, this makes it a lot more efficient over high energy inputs such as corrugations.

Monotube Shock Absorber Disadvantages

Unfortunately, due to the construction of the monotube shock absorber they are more expensive to manufacture creating a trade off between cost and performance. As there is no reserve tube, the shock body also needs to be protected a bit better.

You will often find monotubes mounted upside down to keep the shock body out of the way of rocks and debris from the road. This also gets the mass up onto the chassis and not on the arm which allows the arm to handle the rough conditions a bit better.

Cruisemaster Monotube Shock Absorber Range

Here at Cruisemaster we have 2 monotube shocks on offer, the M46 & the larger, adjustable M60. The standard monotube is the 46mm bore which is on our ATX suspension systems.

The latest Cruisemaster monotube shock is the M60 in the ATX Unleashed range with a 60mm bore. This larger body allows it to store more oil and capture more heat. One of the new design aspects of the M60 monotube is the finned reservoir, which increases the surface area further increasing heat rejection. Another aspect is the adjuster on the reservoir which allows fine tuning to specific conditions whilst on the road.

For a complete breakdown of the Cruisemaster range of shock absorbers and their performance see our Shock Absorber Comparison Chart.

Leaking Shock Absorbers

One of the things to look out for on a shock absorber is leaking oil. Oil on the outside of the body will generally indicate one of two things.

Shock Absorber Misting

The first thing this could indicate is misting, this is where a very light coating of vaporized oil sits on the outside of the shock. This is common when the shocks are worked hard and the oil warms up from the movement of the rod through the seals. At the top of the shock, some of the oil will pass though and vaporize to the outside of the shock.

Misting isn't something to be concerned about and is completely normal. If you notice misting on the outside of the shock, give it a wipe and if there's no additional runs of oil the shock is fine.

Broken or Leaking Shock Absorbers

A leaking shock absorber will have a visual run of oil down the outside of the body, again it is important to wipe the shock down to verify. If the line returns or multiple streaks appear, it is a leaking shock and will need to be replaced.

New Shocks Leaking Oil

Particularly when shocks are new, during gassing on the production line, as the tool comes out of the top of the shock it can drag a bit of oil through causing it to sit on top of the shock. This oil will sit there until it is warmed up during use and will drip down the exterior.

Shock Absorber Servicing

During servicing, at the Towing Performance Centre, they will remove the bottom bolt of the shock and run them through a compression cycle to check the gas pressure is good and everything's working as designed.

Another aspect of maintenance is checking mounts, on dual tube shocks, checking the condition of the rubber bushes and ensuring there is no play is important.

Monotube systems have a spherical bearings, to inspect these ensure they move nicely and there is no play or corrosion.

Next check the mounting bolts and they are nice and tight and torqued to the specifications in the owners manual of your specific system.

For more caravan and towing tips, make sure to keep an eye out for the latest episodes of our Cruisemasterclass series by subscribing to the Cruisemaster YouTube channel and following us on Facebook & Instagram.