Common Electric Brake Wiring Faults & How to Avoid Them

2nd Aug 2023

Brakes are an essential component of recreational trailers and caravans, not only are they a legal requirement for trailers over 750kg, they also help to reduce the strain on the towing vehicle's brakes and improve safety on the road.

When we are talking caravans and camper trailers electric brakes are the most commonly used braking hardware due to their cost effectiveness and relative ease of use. However, electric brake wiring faults can significantly impact their performance and compromise the safety of your vehicle.

In this Cruisemasterclass, we'll discuss the two most common electric brake wiring faults and how to avoid them.

Cruisemasterclass Episode 11: Electric Brake Wiring Faults

Poor Quality Connections

One of the most common issues with electric brake wiring is the quality of the connections. The use of BP connectors for joining the wires is a common fault as these connectors are typically used in domestic electrical systems and are not suitable for mobile vehicles.

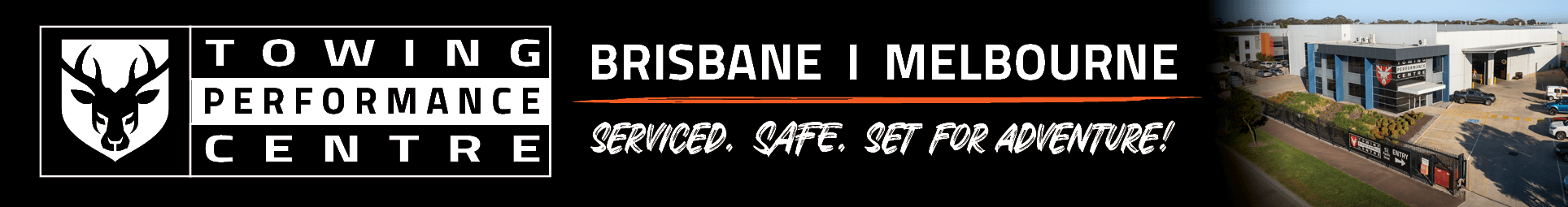

Over time, the brass terminal can vibrate loose from the copper electrodes, leading to poor continuity of the brake wires. Pictured below is an example of BP Connector wiring that has come loose.

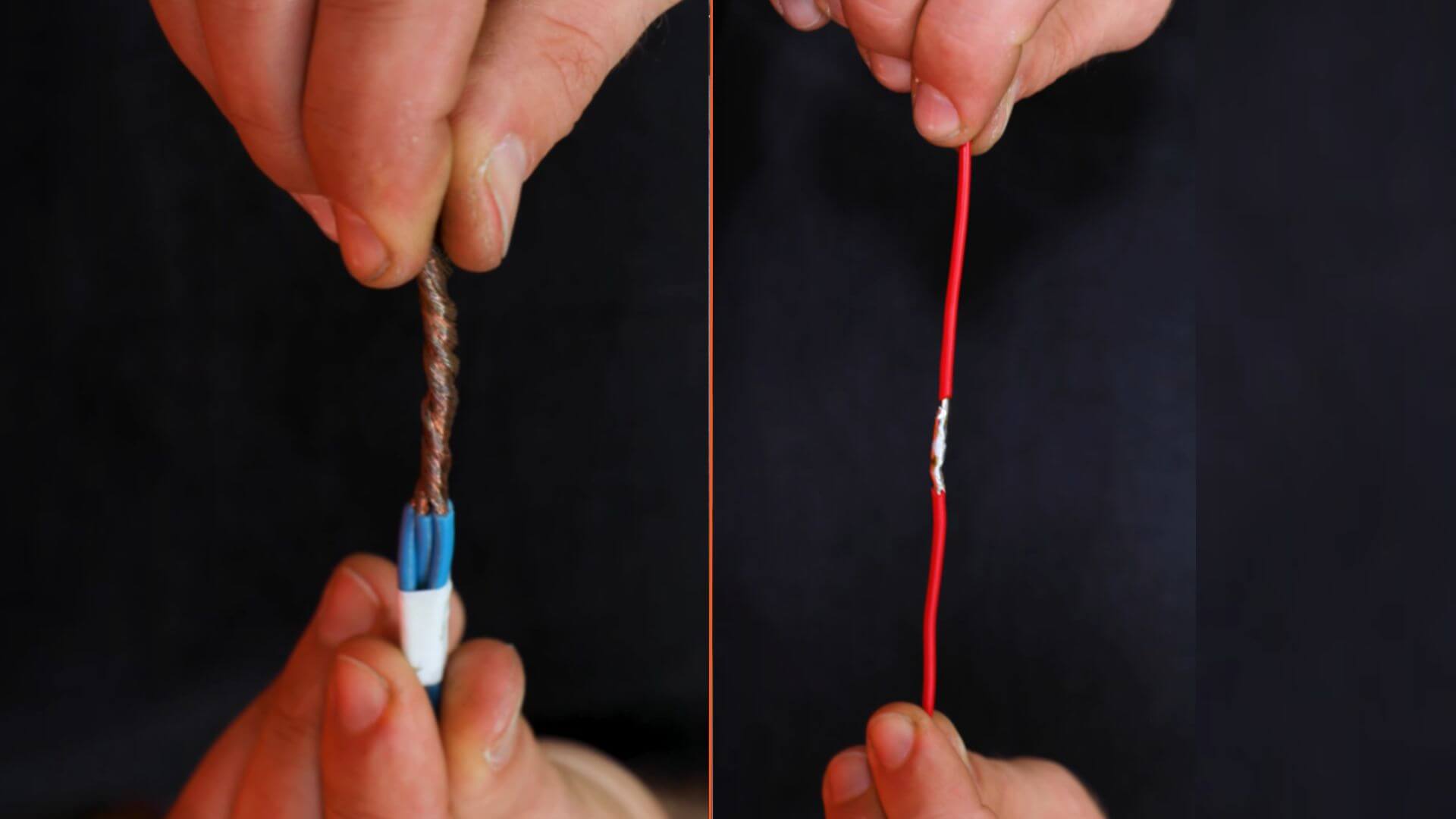

Another common issue we find is that some people don't use a connector and resort to a twist and electrical tape job. This is not an effective solution with a poor connection which can become hazardous on the road, an example of this poor connection is on the left of the image below.

We recommend using a soldered joint (pictured above on the right) covered by heat shrink or a quick-connect plug, such as a Deutsch connector plugs, which are water and dust-sealed and have strain relief to prevent fatigue of the terminal on corrugations.

Voltage Drop

Voltage drop is another significant issue with electric brake wiring. Voltage drop is similar to that of pressure loss in a water pipe, with the longer and smaller a wire is, the more resistance there is to the current flow.

As electric brake torque is dependent on the voltage going into them, voltage drop is a crucial factor that needs to be addressed. It is essential to ensure that the wire is correctly sized to avoid voltage loss.

The Effect of Wire Size on Voltage Drop

The effect of wire size on voltage drop is significant. Using a small wire can result in a voltage drop, even if the current draw is within the wire's capabilities.

In the Cruisemasterclass video, a three-millimeter standard auto cable was used, which is capable of handling ten amps but still resulted in a whole volt drop.

The video also showed the difference in voltage drop when using a six-millimeter twin cable, which had a much smaller voltage drop of 0.4 volts. This demonstrates the importance of using correctly sized wiring to ensure that you're getting the full voltage to your electric brakes.

Electric brake wiring faults can cause significant problems with your vehicle's performance and safety. The most common issues include poor quality connections and voltage drop due to incorrectly sized wires. To avoid these problems, it's important to use high-quality connections and correctly sized wires.

If you have any questions or concerns about electric brakes or wiring, make sure to contact a professional technician who can help you optimize the efficiency of your vehicle's electric brakes. For additional information on trailer electric brakes see our Cruisemaster A/T electric brakes.