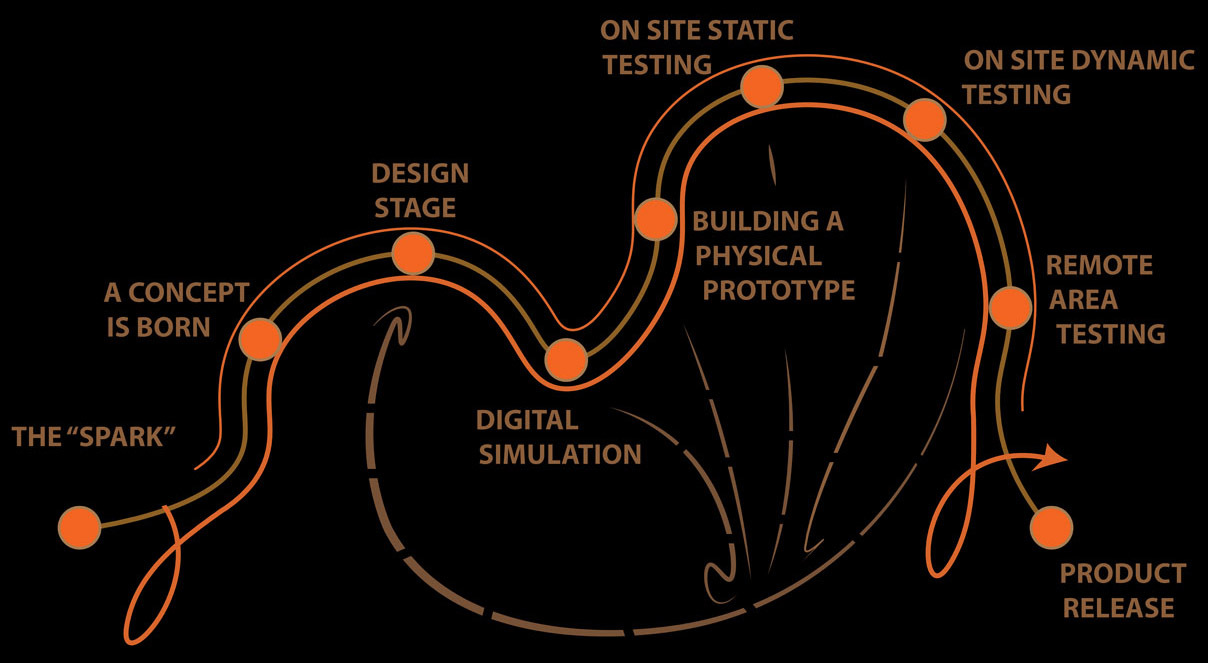

The Long, Hard Road to Release

The Cruisemaster Engineering Journey

At Cruisemaster, our without limits approach makes innovation the heart of everything we do. From initial sketches to real-world testing, our rigorous engineering process ensures that every product we design can tackle the toughest terrains Australia has to offer.

Design

Every great product starts with a solid design. Our engineering team employs advanced CAD (Computer-Aided Design) software to create detailed 3D models of new prototypes and refine existing designs. This precise modelling allows us to simulate the functionality of our products and explore improvements before moving to production.

Finite Element Analysis (FEA)

The first step in our testing process is using Finite Element Analysis (FEA) software to assess the strength, durability, and performance of our designs under simulated stress conditions.

This virtual testing process helps us identify potential weaknesses and optimize materials and design elements for maximum reliability and performance. With FEA, we can confidently create products that are built to withstand extreme off-road conditions.

Lab Testing

Once prototypes are developed, they undergo rigorous testing in our state-of-the-art laboratory. Machines, such as the shock dynamometer, simulate real-world conditions to test the performance of critical components like suspension systems and shock absorbers.

These tests ensure that every part meets our high standards for durability and safety before progressing to field testing.

Track Testing (AARC Test Track)

Lab tests are essential, but we know that real-world performance is the ultimate benchmark. That’s why we put our products through controlled track testing. Completed at the Australian Automotive Research Centre (AARC) test track we simulate a variety of terrains and towing conditions to assess the handling, durability, and overall performance of our products.

One of our latest products to hit the AARC Test Track was our ABS Enabled Caravan Suspension - Check it out on the track here.

Real-World Testing: The R.A.T. Run

Testing doesn’t stop in the lab! At Cruisemaster, we believe that products need to prove their worth in real world conditions. This is why we have completed over 13 Remote Area Testing Runs (R.A.T. Run).

During the R.A.T. Run, prototypes are taken into some of Australia’s most challenging and remote terrains. From Cape York to the infamous Gibb River Rd, we push our products to their limits.

This hands-on approach allows us to capture invaluable real-world data, refine our designs, and ensure that our products exceed expectations when it matters most.

Want a glimpse of the action? Watch the latest R.A.T. Run on our CruisemasterCountry YouTube Channel!