The Importance of Bolted Joints & How They Work

28th Aug 2023

Bolted joints play a crucial role in many mechanical structures, including vehicles, trailers, and machines. Properly tightened bolted joints are critical to ensure that all parts remain in place and function correctly.

In this Cruisemasterclass, we'll take a closer look at how bolted joints work and the importance of correctly tightening bolts. We'll also discuss the different types of nuts and bolts, including nyloc nuts and flange head nuts, along with their roles in maintaining bolted joints.

Cruisemasterclass Episode 14: Bolted Joints

How Bolted Joints Work

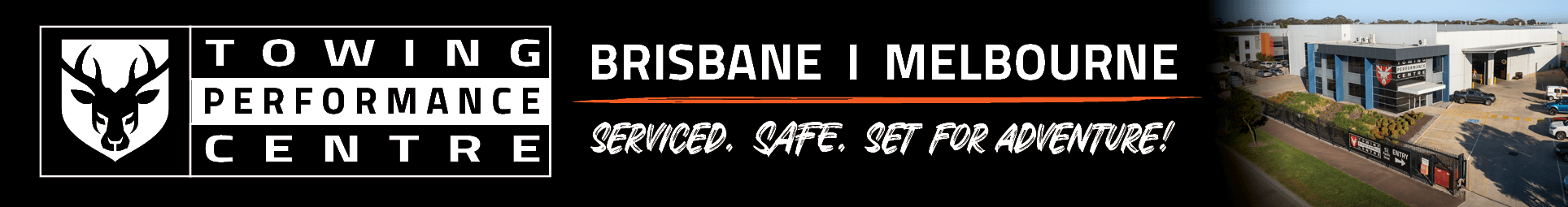

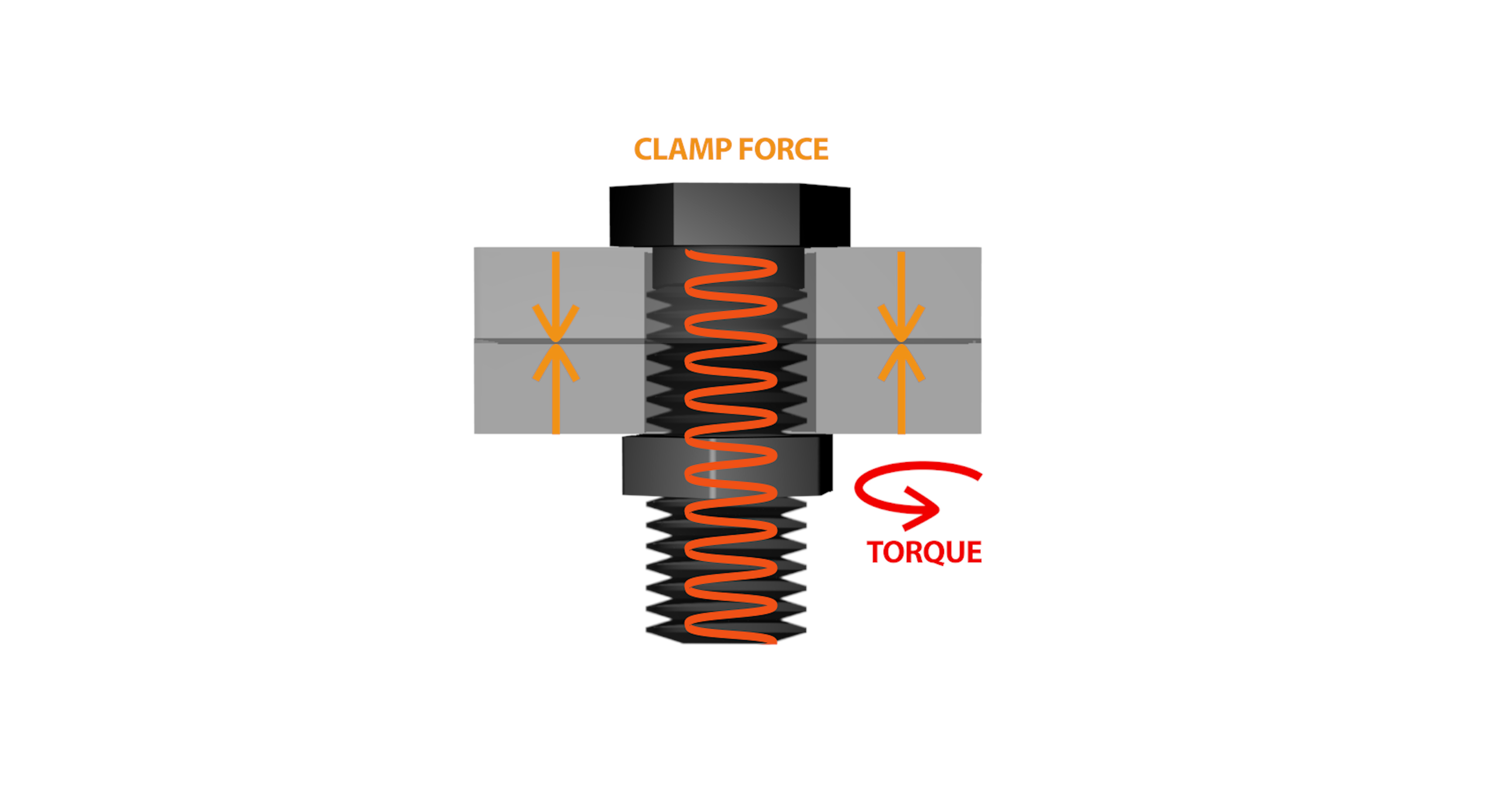

Contrary to popular belief, the bolt itself doesn't resist the force in a bolted joint. Instead, when you tighten the nut and the bolt together, the bolt elastically stretches and generates force (clamp force) on the joint, much like a spring.

This force is created because of the friction between the two plates that are being joined together. When the bolt is correctly tightened, this force keeps the plates in place.

However, if the bolt is not tightened correctly, there won't be enough friction between the plates, and the joint will become loose. In this case, the force will end up on the bolt, which can lead to fatigue and ultimately, breakage.

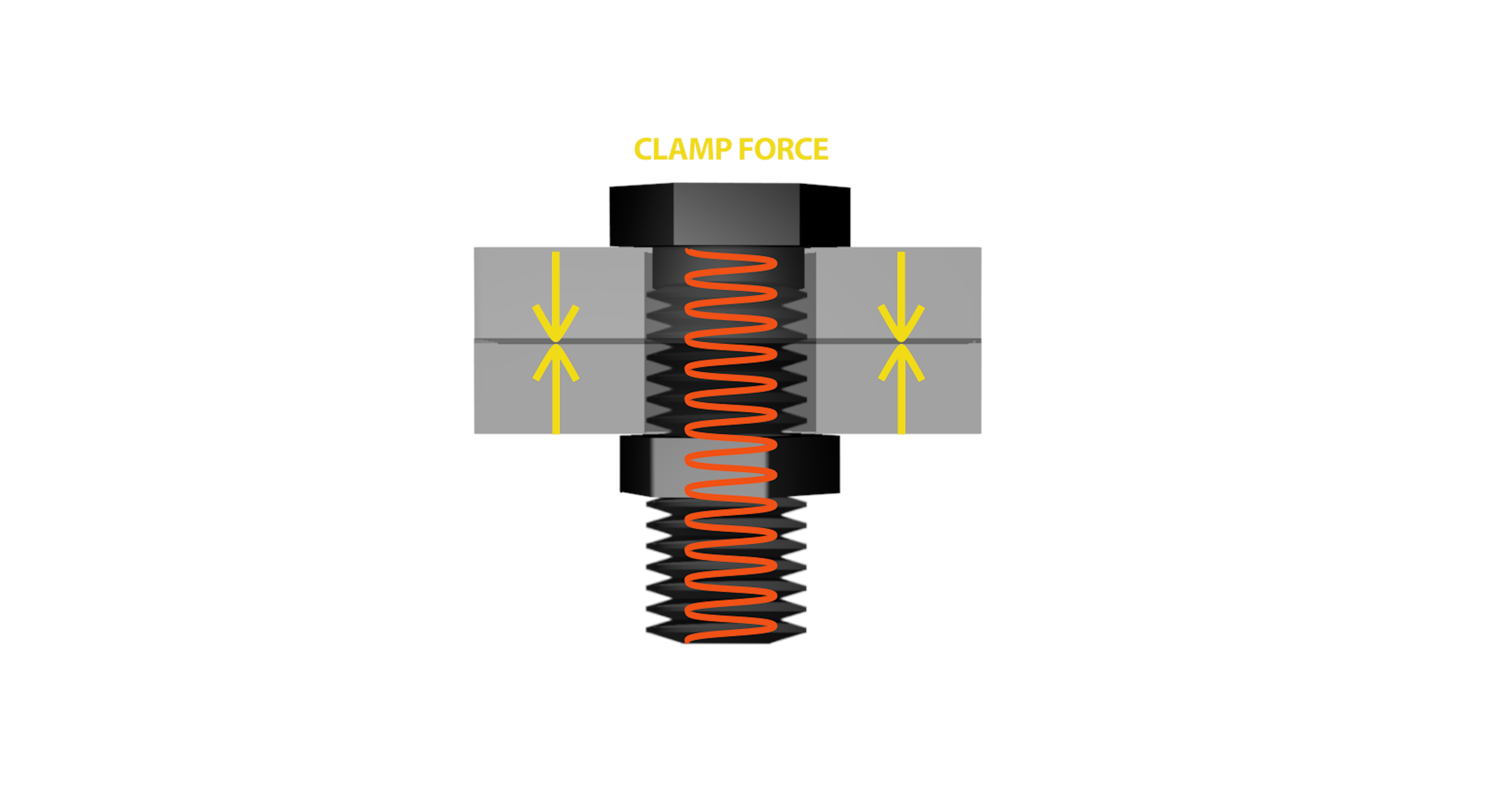

The Role of Torque Wrenches in Tightening Bolts

To ensure that the correct force is generated on bolted joints it is important to use a calibrated torque wrench to tighten bolts. While experienced people may be able to get the right tension by feel, using a torque wrench is the only way to guarantee accurate results.

All Cruisemaster products come with a spec sheet that defines all the torques required to fasten the product's suspension and couplings. These numbers should be dialed into the torque wrench and used for the initial installation.

Critical bolts should also be checked at subsequent services to ensure that they maintain their torque and haven't moved. If you are travelling on particularly harsh roads or corrugations you should inspect components more frequently to ensure nothing has come loose.

Components of Bolted Joints

Nyloc Nuts

These nuts are designed to prevent the nut from loosening due to fluctuations in forces that go through the joint. They work by providing a secure grip on the bolt, so it can't come loose.

It is important to torque Nyloc nuts to the manufactures specified torque to ensure there is enough force to resist vibrations.

Thread Locker

Thread locker is a type of adhesive that bonds the nut and the bolt together. This bond prevents the nut from coming off, even if the joint becomes loose.

Spring Washers

Spring washers work by digging into the plate and the head of the nut if the bolt loosens. This digging action helps to resist the nut from unscrewing off the bolt.

Flange Head Nuts and Bolts

Flange head nuts and bolts are designed to spread the pressure generated by the clamp force over a larger area. This prevents the heads from embedding themselves into the plates, which can result in the loss of pre-tension in the bolt.

For more caravan and towing tips, make sure to keep an eye out for the latest episodes of our Cruisemasterclass series by subscribing to the Cruisemaster YouTube channel and following us on Facebook & Instagram.