Air Suspension Leaks, Faults and Maintenance

26th Jul 2024

In this CruisemasterClass we cover techniques for troubleshooting leaking trailer air suspensions along with maintenance tips to help prolong the life of your system.

Cruisemasterclass Episode 22: Air Suspension Leaks, Faults and Maintenance

Common Causes of Air Bag Leaks & Damages

The first thing we will be looking at are the common causes of air bag leaks. In most cases the bag itself is not the cause of the leak, with loose or broken air lines being the typical culprit. Below we will explore the most common causes of air bag leaks and damage.

Installation Problems

One of the most common causes of leaking air systems is due to incorrect installation as this can lead to components rubbing against the air bag leading to a puncture. For Cruisemaster systems you can ensure your air system is installed correctly by referring to our installation instructions on our downloads page.

Correctly Cutting Air Lines

Incorrectly cut air lines are a common pain point for air suspension leaks with non flush or poorly cut lines allowing air pressure to escape from the system. Cutting the airline correctly with the cutting tool provided in the Cruisemaster air kits will ensure the line is able to make a secure connection with the connectors.

Correctly cutting air lines with a cutting tool.

Debris

Debris is another cause of airbag leaks, with sharp rocks or sticks caught in airbags able to rub against bags which in time cause a puncture. Regularly checking for and removing debris can help mitigate the risk of airbag damage.

How to Find Leaks in Airbag Suspension Systems

The easiest way to detect air system leaks is with a spray bottle filled with a soapy water solution. The mixture is sprayed onto the system components to detect air leaks, with small bubbles forming in the liquid to identify air escaping.

Applying soapy water solution to identify air leaks.

Bubbles in air fitting, identifying air leak.

Make sure to check the air bags, lines, air tank, valve manifold, solenoids and air compressor connections. Another tell tale sign that your air system isn't holding air pressure is the air compressor constantly on trying to build tank pressure.

As the compressor has sensors to measure air pressure, small leaks will cause them to continue to run, which can cause premature wear of parts.

Spare Parts & Emergency Repair Kits

In the unfortunate event of finding a leak in your air suspension system, there are emergency kits available to pack in your car or caravan/ trailer to keep you on the road. These kits include spare airline, cutters and spare fittings, you can purchase our air system emergency repair kit direct through the Cruisemaster webstore.

Air Suspension System Maintenance

While air bag suspensions are reasonably self sufficient, there are a few maintenance steps you should take to help prolong the life of your system.

The first thing you'll want to do is give the system a visual inspection prior to hitting the road for any obvious signs of damage. This should include checking all fittings are still firmly connected and the system is free of debris. You should also check the air bags for any evidence of rubbing or abrasions

Damaged airbag, with signs of abrasion.

How to Drain Water Out Of Air Suspension Systems

Another regular maintenance for air suspensions is to drain the condensation out of the air tank to prevent excess moisture build up. This is done by first turning your compressor off and releasing any built up pressure inside of the tank.

You will then have to locate and open the tanks drain valve. When doing this make sure the tank is tilted towards the valve to allow all of the moisture to easily drain. Once all the moisture has drained from the system make sure to close the valve.

Draining the air tank before storing your van will help prolong the life of the tank and the system

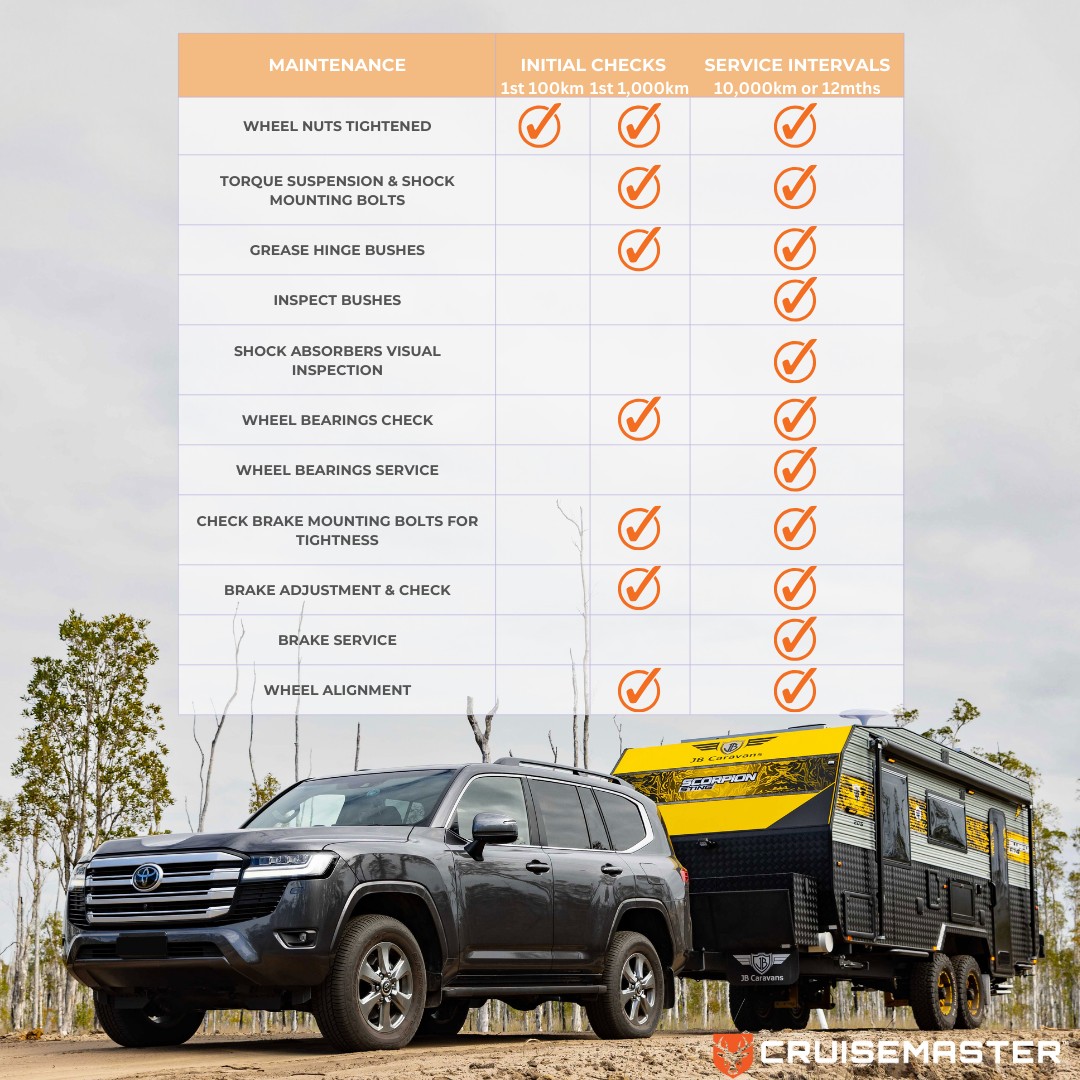

Annual Servicing & Maintenance Frequency

One of the most important regular maintenance steps is to keep the system components clean. So after returning from your trip make sure to clean off any salt water, dirt, gravel and debris. This can be done using a hose or a soft brush with soapy water.

When cleaning check the bags for objects such as rocks and sticks and remove them to prevent rubbing and punctures.

Lastly you'll want to regularly check the torque bolts of mounting hardware and air lines to ensure nothing has come loose. You can verify your air lines are secure by giving them a gentle wiggle, and use a torque wrench on bolts to ensure the are up to the torque specs outlined in the user manual. User manuals are available for the complete Cruisemaster range of suspension systems and towing products on our resource page.

These checks should be done at least every 6 months or in line with your caravans regular servicing. You should also check this after particularly rough or long trips, such as on prolonged corrugations.

For more caravan and towing tips, make sure to keep an eye out for the latest episodes of our Cruisemasterclass series by subscribing to the Cruisemaster YouTube channel and following us on Facebook & Instagram.